Compressive Strength (@28days)

> 15 N/ Mm2

Package

40 Kg/Bag

Colour

Grey / White

Water powder ratio (For Mixing purpose)

Welcome to Shree Premix Industries (SPI), a leading manufacturer and supplier of high-quality building materials, including Thin Bed Block joining Mortar. At SPI, we understand that the quality of construction materials is essential for any building project, and we are committed to providing our customers with the best products available.

We offer a wide range of Thin Bed Block joining Mortars, including A.A.C. Block Joining Mortar, Readymix Block Joining Mortar, Self-Curing Block joining Mortar, and Chira Stone Joining Mortar. Our products are designed to meet the needs of modern construction projects and provide exceptional adhesion and durability.

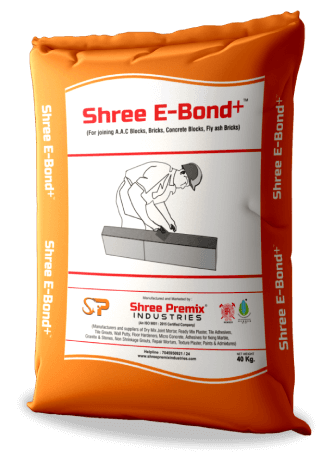

Shree E Bond+ is our flagship product, a premium quality Thin Bed Block joining Mortar that is designed to provide superior bonding strength and long-lasting performance. It is suitable for use with a variety of building materials, including concrete blocks, AAC blocks, and fly ash bricks. Shree E Bond+ is easy to use and can be applied quickly and efficiently, saving time and labour costs on your construction projects. It is also resistant to water and moisture, ensuring that your building remains strong and stable over the time.

We also offer Self Curing Block joining Mortar, Self-Curing Concrete Block Joining Mortar, Non-shrink A.A.C. Block Joining Mortar, and Eco-Friendly A.A.C. Block Joining Mortar. Our Self Curing Block joining Mortar is designed to reduce the need for external curing, saving time and labour costs. Our Non-shrink A.A.C. Block Joining Mortar is specially formulated to provide exceptional adhesion and prevent shrinkage during the curing process. Our Eco-Friendly A.A.C. Block Joining Mortar is designed to be environmentally friendly, with low VOC emissions and minimum waste.

We also offer Waterproof Block joining Mortar, which is specially formulated to resist water and moisture, making it an ideal choice for buildings located in areas with high rainfall or humidity.

At Shree Premix Industries (SPI), we are committed to providing our customers with the highest level of quality and service. We use only the finest raw materials and apply rigorous quality control standards to ensure that our products meet or exceed industry standards. Our team of experts is always available to provide advice and support, ensuring that you get the right product for your specific needs.

In addition to our Thin Bed Block joining Mortars, we also offer a range of other high-quality building materials, including ready-mix concrete, dry mix plaster, and tile adhesive. Our products are designed to make your construction projects easier, faster, and more cost-effective, while also ensuring the highest levels of quality and durability.

If you are looking for a reliable and high-quality supplier of Thin Bed Block joining Mortar, look no further than Shree Premix Industries. Contact us today to learn more about our products and services, and to see how we can help you with your construction needs.

Shree Premix Industries (SPI) was Established on Feb 1, 2016 by Mr. Yuvraj P. Patil. More than 30 years versatile Experienced "Civil Engineer”: Who has worked in Two Big Esteem Organizations "M/s. Siporex India PVT LTD" at their Mumbai Office and "M/s. Flyocrete Green Concrete LLP" at Nasik and Mumbai Office respectively at Management level position

Description

Shree E-Bond+ is a Polymer modified Pre blended Thin Bed, non Curing, Readymix mortar for fixing A.A.C /Concrete Block / Stone / Chira / Bricks / Fly ash Brick

ASTM Ref : ASTM C-1660-10 : Standard specification for thin bed mortar for Autoclave Aerated Concrete (A.A.C.) masonry

AREA OF APPLICATIONS

For joining A.A.C Blocks/ Concrete Blocks/ Bricks/ Fly ash Bricks in all type of masonary of residential/ Commercials/ Industrial/ Institutional Buildings, Malls,Multiplex, Public Buildings, Hotel, Hospitals, Government, Semi government projects, Railway, PWD, CPWD, MHADA, Pantpradhan Avas Yojna, Swatch Bharat Abhiyan (Toilet Project), SRA, Redevelopment, Affordable Housing Projects, Religious Place, Heritage structure, Ware housing projects and various types of projects.

For Walls

For Ledge Walls

Load Test More Than 250kg*

(For M15 Variant)

Advantages

Self curing property skip the curing to the masonary hence it save time, water & man power cost.

No need of special skill persons for using "Shree E-Bond+" hence skip the supervision and quality control activities at site.

Quantity of Shree E-Bond+ required are very less in masonary compared to conventional method, hence it will useful in the area of having shortage of sand & water.

High Compressive & Splitting Tensile Strength than others.

Pot life of "Shree E-Bond+" is more hence we can continue the masonary work for long time & avoid wastage of mixed mortar

Speed of masonary work is more if use of "Shree E-Bond+" & masonary get more strength in lesser time hence finishing work (plastering & painting) on wall can be Done earlier.

"Shree E-Bond+" has hydrophobic property hence it prevents the water to penetrate through the mortar in masonary.

Thickness of "Shree E-Bond+" mortar joint will be 2 /3mm against in conventional method joint thickness 10mm /25mm.

Easy availability & quick delivery of “Shree E-Bond+” avoids more investment to the keep stock.

High strength & uniform quality throughout the year by regular quality control of raw materials & finished goods.

Use of "Shree E-Bond+" saves the labour cost, avoids wastage, easy accountability, traceability of material consumed / balance as well as keeps site neat & clean.

Use of "Shree E-Bond+" saves the cost of hacking & bonding agent required for joining the masonary between two columns/r.C.C members.

"Shree E-Bond+" having property of non shrinkage, shock and impact resistant which avoids crack in the mortar.

Use of "Shree E-Bond+" in masonary saves the time & interest cost due to early completion of the project.

Applications

Technical details

To Know More About Technical Specification In Detail

How To Use

Do not use or mix any other material in "Shree E-Bond+" except water. In case of mechanical mixer "Shree E-Bond+", shall be added in 180-200ml/kg clean water & mix for 3 mins & in case of hand Mixing "shreee-bond+",shall be added in 210-220 ml clean water & mix for 8 to 10 mins, till we get the required consistency. After addition of "Shree E-Bond+" in water, mix it thoroughly in mixing trey / pot / mechanical mixer till we get smooth uniform workable consistency, allow mix for 3 to 5 minutes to Remain idle for additives to dissolve to get required properties to “Shree E-Bond+” & again mix the "Shree E-Bond+" to get workable consistency.

Remove the dust particles, clean the surfaces of blocks/ bricks and wet the surfaces. Floor level/ surface for laying the blocks in the masonary shall be in Level, structurally sound to avoid any cracks in the masonary, it shall be checked before starting the masonary otherwise leveling of the surface shall be Done first. Curing compound shall be removed from the R.C.C surface.

After cleaning the surfaces of the R.C.C columns by wire brush, blocks, wet the surface with water by using brush, apply 2 to 3 mm thickness of "Shree E-Bond+" on horizontal and vertical surfaces by notch trowel to avoid wastage & to get uniform thickness as well as for proper bonding. After laying Blocks in level on “Shree E-Bond+”, slightly hammer it with rubber mallet for proper fixing, alignment as well as to remove excess material below the Blocks by closing the voids if any, same procedure of laying blocks in masonary shall be followed. For the design of wall I.E. Thickness, height, length as Well as for the strength & stability is: 1905 - 1987 (2002) and for the construction of A.A.C. Block masonary IS: 6041-1985 (R 2005) shall be followed. For proper result of "Shree E-Bond+" layer of blocks/ masonary shall not be disturb for minimum first 24 hours.

In case of manual mixing hand gloves shall be used.

"Shree E-Bond+" is non-toxic. Use of gloves and goggles recommended. In case of contact with body, eye & face wash it with sufficient water.

Unloading and Storage

Do Not Use Hook

Do not use hook for unloading, shifting of bags, material

Loaded Above Ground Level

It shall be unloaded on uniform level platform surface above ground level with proper stacking in countable manner

Store In Dry Place

It should be stored in covered dry place.In case of rainy season it shall be stored in closed store room by covering it by tarpaulin / polythene sheet to protect the bags from dampness / humidity in the atmosphere.